There's more to buffing than you may think!

Most of us are fairly familiar with the term buffing, which is the process of levelling out your polish, wax or another applied product in order to create a shine to your paintwork. However, grabbing the nearest cloth and rubbing the residue off can cause harm to the finish if not carried out correctly!

Why do we buff?

When you apply a polish or wax only a small percentage of that product will actually bond to the paint, hence “less is more” and “too much” is a waste. Imagine, if you will, applying a thick layer of butter to your warm toast…. The butter which is in contact with the toast will slowly melt in and become absorbed whilst the top will remain there for a small period of time.

You will learn from our 'Wax Ghosting' article that additional complications come from using too much product and this can have a detrimental effect on your finish.

Allowing the product to haze

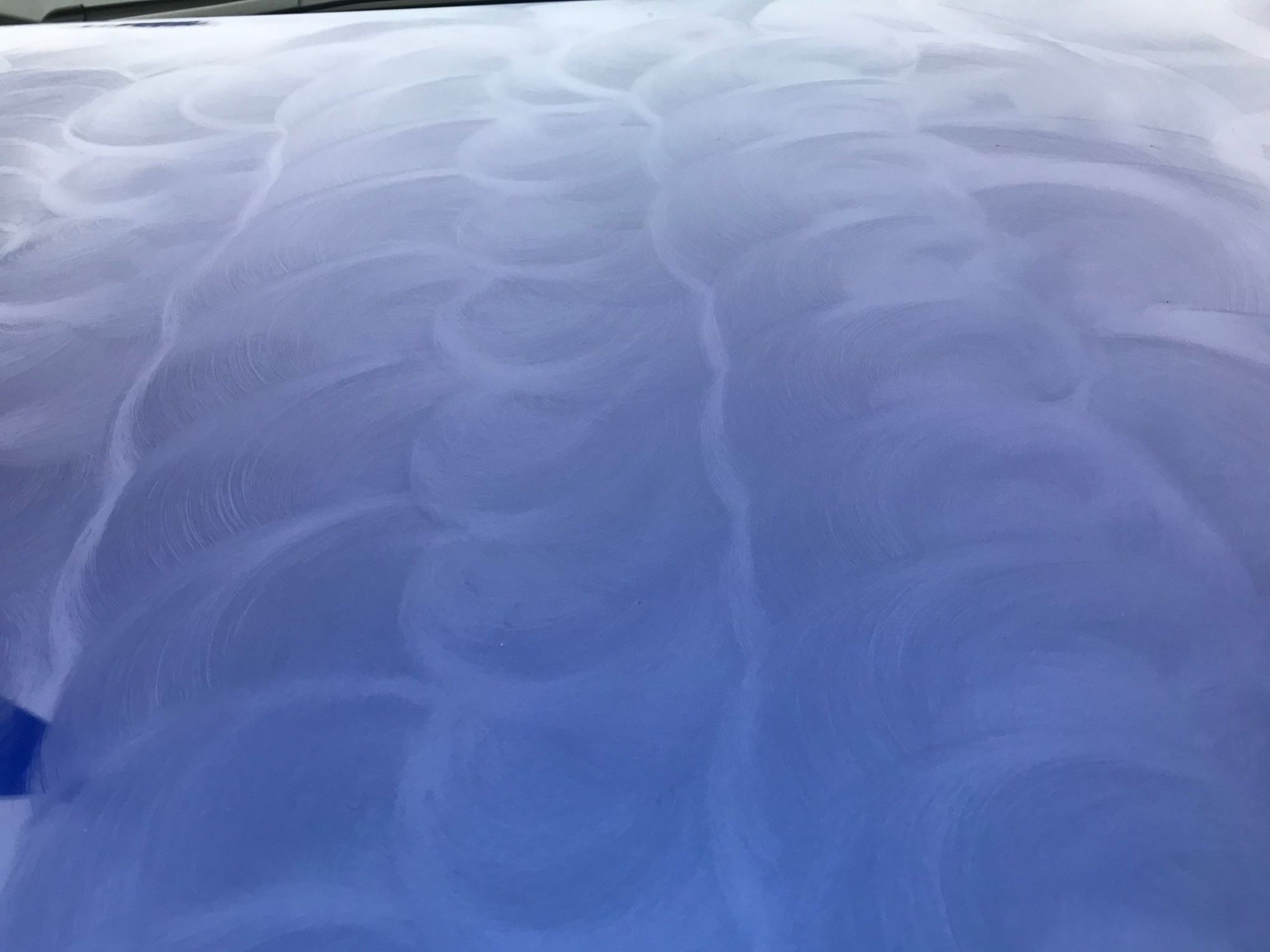

With a suitable amount of product applied to your paintwork, any solvents or liquids contained within it will start to evaporate off and leave your paintwork hazy and it is at this point when you can run your finger through it leaving a clean line that you know the product is ready to be buffed off.

This hazy/less translucent layer is known as product residue and needs to be removed in a careful manner.

Points to note

In order to significantly reduce the risk of marring through the buffing process, some considerations are necessary:

-

Quality. Our 'Microfibre Guide' provides much detail on the importance of microfibres. Specifically for buffing, we strongly recommend coral fleece microfibres (article here about coral fleece)

-

Cleanliness. It is essential to use a clean microfibre to ensure no contamination is introduced, whether that be dust or previous product residue. For example, using a microfibre that has been previously used for removing wax residue should not to be used when removing polish as it will leave wax residue on the paint surface, contaminate the product that you are trying to buff off and possibly have a detrimental effect on the performance of that product and the overal finish.

-

Contamination. Having an extremely clean and contamination free paint surface is crucial. Even areas nearby which you are not working on need to be clean and free from contamination so as you do not accidently drag grit, dust etc into the target area during the buffing process, thereby causing unwanted marring.

-

Pressure. Use little to no pressure when buffing. Any mechanical or physical pressure applied during the buffing process can introduce marring, swirls or other imperfections especially if you are not careful with your processes and choice of microfibres.

-

Folding/turning. Turn your microfibre frequently so that you are using the cleanest part as much as possible. Product residue absorbed into the microfibre will be coarse to a certain extent and continually rubbing that over the surface will add imperfections as previously described.

-

Speed. Speed is important to both the application and buffing processes. Using a machine polisher to apply a compound or polish obviously uses high speed, but when it comes to applying a finishing polish and refining the finished surface, a low speed it recommended. Known as “jeweling”, the art of perfecting the paint surface requires a specific process where speed should be as low as possible. This will be explained more in a forthcoming article

When it comes to buffing, work slowly and deliberately, taking care of the processes you are using as these will aid the finish. Buffing quickly will cause friction and attract dust and result in areas being missed. Buff slowly taking care and time will yield better results.

-

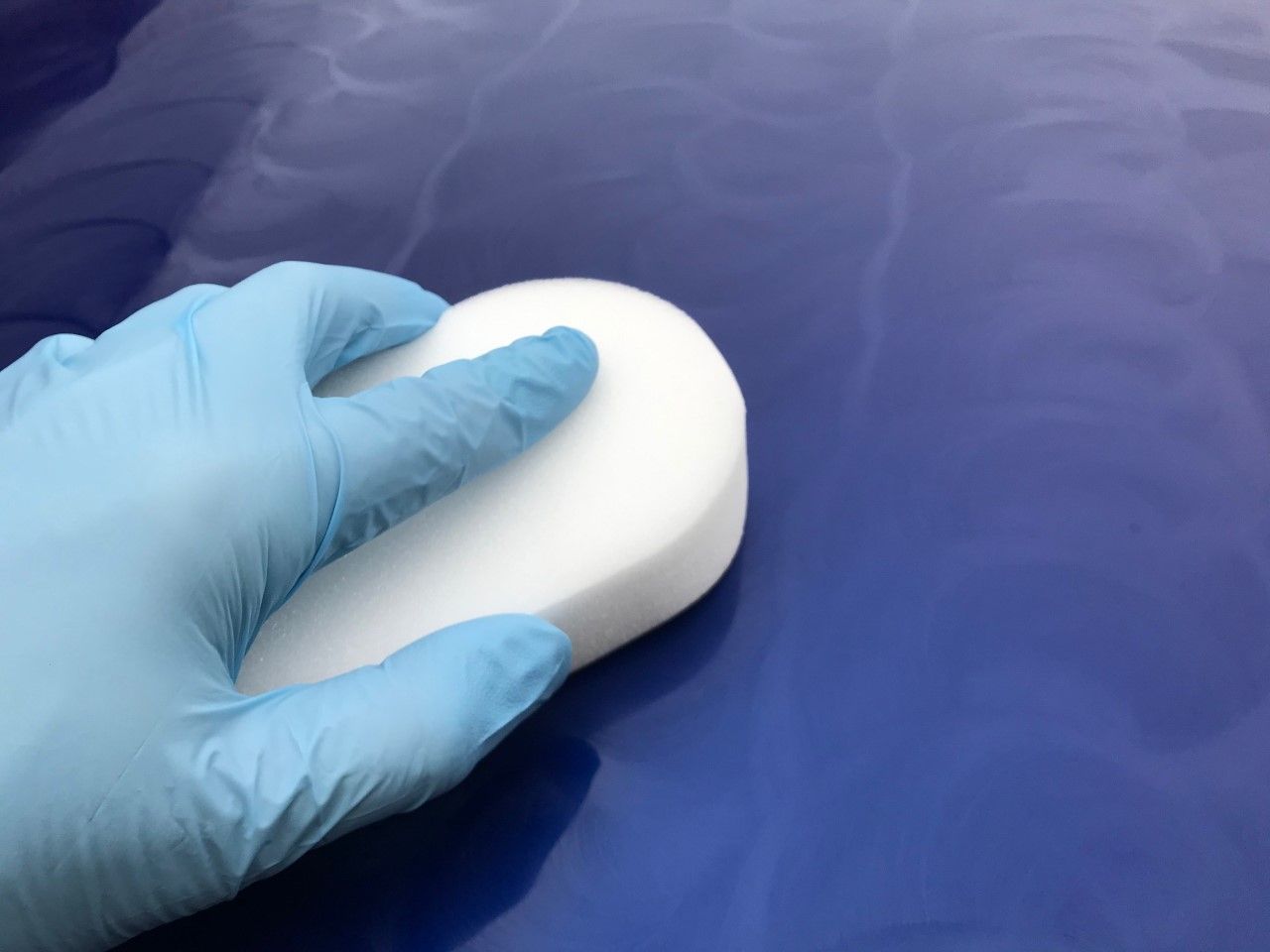

Gloves. It's always wise to wear detailing gloves for a number of reasons. Firstly, it prevents the transfer of natural oils on your hands onto the cloth which is coming in contact with your paintwork and secondly for health issues; more can be read in our 'Detailing Gloves' guide.

Machine buffing

You can use a machine to buff products off. Always use exceptionally clean buffing pads and a slower speed than the application of products is recommended. Machine buffing can be quicker and can produce some good results, but generally using a deep pile microfibre will return better results.

A machine is necessary for jeweling, however the use of a microfibre is still required for that ultimate buff!

Availability

We provide a wide selection of microfibres for all processes of detailing, so it’s advised that you read the product description before purchase. As mentioned above, our finest finishing microfibre is the Microfibre Edgeless Plush Coral Fleece Finishing Cloth 450GSM. Supremely soft, deep pile and regarded as the finest on the market. You can read more about it on the listing and also in our Coral Fleece article.