Why a smooth paint surface is crucial for so many reasons!

We spend many hours cleaning, polishing and waxing our cars, and in most cases we are happy with the results, albeit we know deep down it could probably be better! So does understanding a little science and a bit more about the products and processes help us achieve that ‘show room shine’? Well the answer is a firm yes!!

There are many products, stages and processes required to get your paintwork ‘above average’. This guide will talk about the fundamental requirement of the need to have a clean and smooth surface.

What is a ‘clean surface’

Our cars are parked outside for the majority of the time and as such a result are bombarded by a plethora of harmful substances. These can include dirt, ferrous particles (containing iron), industrial fallout, contaminants, bird mess, acid rain, road tar, tree sap, brake dust and more. These embed themselves into the paint and clear coat and over time become harmful and discolour and diminish your paints shine.

Simply washing your car will not remove all of these harmful substances and, whilst your car may look clean, deep down it is far from it! Adding a layer of wax onto this contaminated surface will provide much less protection and shine than the product was designed to achieve and you will find it much harder to apply, remove and subsequently maintain thereafter.

A ’clean surface’ is therefore defined as both above and below surface contaminants having been removed and a chemical cleaner been applied to the paint in order to remove all harmful substances.

A true shine?

For this we need a perfectly flat surface. This can be achieved in many ways, including polishing (by hand or by machine), removing embedded contaminants and using hybrid sealants (explained later), glazes and waxes, wet sanding, removing orange peel etc. We need to remove embedded contaminants which can only be done with claying (read more here....)

A ‘shine’ is simply the concept of light reflection and refraction. Unless the paint surface is correctly cleaned and levelled, the surface will not provide a perfect shine and its ability to reflect light and other attributes such as colour, clarity and depth will be significantly reduced.

Colour, clarity and depth

These are 3 factors that Concours d'élégance judges look for when scrutinising paint surfaces. High levels of surface preparation are the key to achieving that perfectly smooth finish allowing product clarity which in turn allows the paints natural gloss to attain its full potential. Insufficient curing and poorly controlled product application will result in a less transparent surface, effectively masking the true colours; more of that later…

If a surface is ‘microscopically’ dirty, then any wax applied on top of the dirt will only result in a shiny layer over a dull surface. With a ‘clean’ surface, you will achieve a deep smooth and more importantly, an optically perfect shine, allowing the wax to jet (a wetting of the surface, commonly known as a ‘wet look’).

Knowing your products

Having a perfectly smooth surface is only one step of in achieving your ‘show room shine’ – granted it is the most important as already discussed, but what products you use and the methodology are arguably equally as important! There is no ‘one’ product that can produce all of the properties of an optically perfect shine, however understanding how each performs will help you.

We now know that simply washing your car and applying a layer of wax without ensuring the surface is ‘clean’ will not achieve a great deal. An optically perfect shine comprises of a number of elements; a ‘clean’ surface, a ‘smooth’ surface and the ‘correct’ methodology of products. If we want a high surface gloss and high surface reflectance then we can use a combination of products such as polymer sealants for their ultimate protection and durability properties, fine surface abrasion and filling abilities, plus a carnauba wax for their three-dimensional jetting properties.

Using a polymer sealant on its own will compromise your paint visually as polymer sealants are far less transparent and tend to cloud/haze over on the surface. Using a wax on its own will provide greater shine but less durability.

Wax vs Polymer Sealant

Carnauba waxes contain oils which in turn produce gloss and subsequently jetting. This effect works by distorting the light reflectance and giving the surface the appearance of rippling liquid, adding a three-dimensional aspect, depth of colour, warmth and richness. In contrast, other waxes such as paraffin, bees wax, synthetic waxes (man-made) and polymer sealants are far less transparent as mentioned earlier.

Polymer sealants are protective products that are made out of polymers (materials made of long and repeating chains of molecules) with no natural products; if they contain wax, they are considered hybrids. They contain very fine abrasive particles which can reduce light swirl marks and oxidisation.

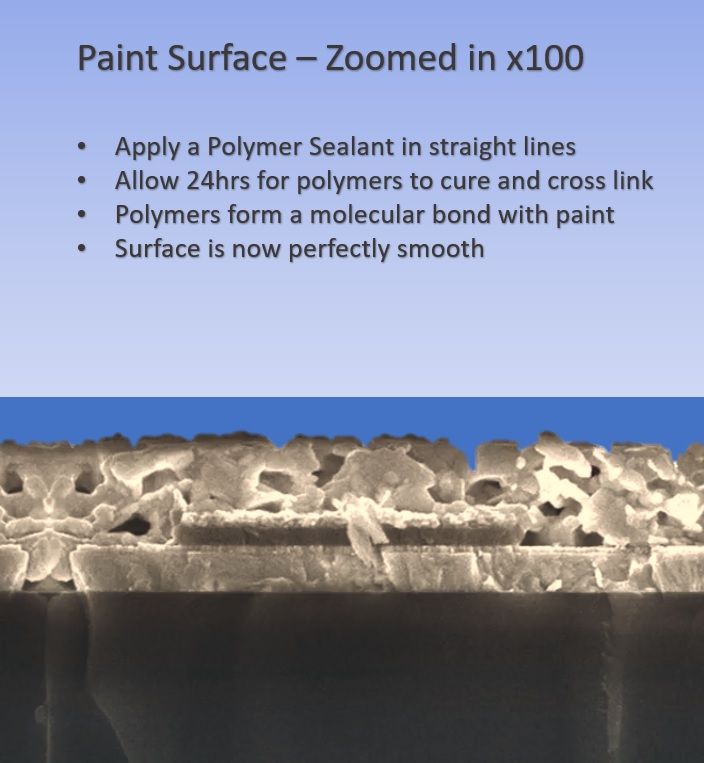

Polymer sealants require a porous surface to bond to which is why we need that ‘clean’ surface and why they are applied before waxes (apply in straight lines to reduce any chance of micro marring as light reflects less on straight line marring than circular marring). Polymer sealants initially adhere by surface tension and then, during the curing process, the polymers start to cross-link and form a ‘covalent’ (molecular) bond to the surface. The curing time from product to product but generally it is 24hrs (temperature and humidity can affect times).

Drying vs curing

It should be noted that drying and curing are two different processes and are often a misnomer. Drying refers to evaporation of the solvents used in the product, whereas curing refers to polymerisation (cross-linking), which produces adhesion, binds the pigments together, and strongly influences such properties as gloss potential, exterior durability, flexibility, and toughness. Additionally, it should be noted that if the polymer sealant is exposed to contamination during the curing process, then this will prevent the polymers from achieving their full potential, reducing performance and durability. This is why the surface needs to remain dry and clean during the 24hr curing process.

With successful cross-linking, the polymer becomes much harder and protective than a wax does and as such its durability is significantly higher than wax. The curing process of a wax is much less (up to 12hrs) and wax doesn’t form the same ‘hard’ coating a polymer sealant does, but rather it absorbs into the paint giving it that three-dimensional appearance and the other qualities already explained.

Maintaining that shine

After all is said and done, we simply cannot just sit back and admire our ‘show room shine’ forever! We need to keep on top of it and maintain that surface.

Following the correct processes during maintenance washes, including using snow foam, a pH neutral shampoo (neither acidic nor alkaline and does contain harsh chemicals which may remove your wax), soft microfibre towels etc are basic requirements to reduce swirl marks and marring which will diminish your shine and protection properties. Furthermore, the removal of wax is a necessary step before a protective product is reapplied or indeed before polishing.

Wax has a limited lifespan and deteriorates over time. The removal of old wax is necessary because it will have absorbed contamination as previously explained at the start; the wax will literally have got dirty! If you add another layer of wax over an old layer which has absorbed much contamination, you are only adding a gloss over a dirty layer of wax. This risks marring and swirl marks during its application and reduces it shine and reflective properties that you spent so long in achieving. The life span of wax applied over dirt is reduced and in short, you are wasting your time and money.

Summary

The final result you achieve will only be as good as the surface it’s applied to and of course the products you use. It’s estimated that your final result is down to 85% preparation, 5% product and 10% methodology. Your cars appearance is very subjective, as is the choice of products and there is no ‘best product’. What matters is that, if it looks good to you, then that’s all that counts.