Microfibre Guide

Microfibre products have been around for over 20yrs but surprisingly less than 25% of car owners use microfibre products for detailing their cars! Arguably the most important piece of kit in your detailing arsenal, here’s a guide about microfibre.

What is Microfibre?

Where better place to start than Wikipedia!

In layman’s terms, it’s the terminology used to describe ultra-fine manufactured fibres and also the technology of making these fibres! Fibres which are made using this Microfibre Technology produce fibres which weigh less than 0.10 Denier (a unit of measure for the linear mass density of fibres) Fibres which are made in this way produce incredible softness. Each fibre is 2 times finer than silk, 3 times finer than cotton, 8 times finer than wool and 100 times finer than a human hair!

Types of Microfibre

There are a number of different types of microfibres being produced currently, with the most common being a combination of Polyester and Nylon (Polyamide). Polyamide makes up the smaller percentage of the total microfibre weave, usually 20-30% with Polyester making up 70-80%. Those microfibres with 80% Polyester and 20% Polyamide are the preferred choice for tackling automotive substances you come across and provide a very soft microfibre for buffing. Opt for a 70% Polyester and 30% Polyamide and your stepping up a level to a more luxurious and highly absorbant fibre.

Each of these fibres in themselves have different qualities:

- Polyester. Used to remove or scrape away microscopic particles of dirt

- Polyamide. Used to absorb liquids into the fibre

Exploring further into the different types of microfibre, the following are the most common:

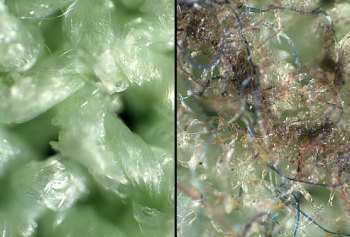

Split fibre: A Split microfibre is the base characteristic of a microfibre. This process of splitting provides an incredible amount of surface area. A microfibre thread with a width of 0.13 Denier has a surface area of 5 miles per 1 gram and is only achieved by splitting these Denier sized fibres. This splitting is crucial in creating softness, absorbency and the ability to grab dust, dirt and contaminants, and even more importantly, removing them from the surface. This is why it is so important to know that the microfibre you purchase is split in this way. It goes without saying that this process costs far more money to make these split fibres, but if they are not split like cheap microfibres, then the microfibre will be an inferior product.

Coral Fleece: The softest cloth you will find on the market. High-tech split fibres have a thickness less than 0.1 deniers, which is 10 times finer than silk and 100 times finer than the human hair

Closed loop: Split fibres are woven into a loop rather than leaving open ends. It is often finished with a non-stitched edge and the closed loop construction leaves behind no lint or streaking. Ideal for glass and mirrors.

Twisted Loop: The newest technology in microfibres, this unique design bundles fibres in a very compact twisted orientation. This construction greatly increases the surface area allowing for higher absorbency and faster drying, whilst creating less friction when wiping.

Waffle Weave: This is a wonderful towel for drying any automotive surface. The waffle pattern provides and incredible amount of surface area with the lower places in the weave designed to absorb the water. These are easily wrung out and very durable.

Automotive Glass and Mirror: These microfibres have a very short pile and are usually woven into a ‘corduroy’ pattern. It is rougher and more aggressive than the Terry for example but can still maintain good absorbency. These are ideal for glass and mirrors or surfaces which can scratch very easily. Always choose a high quality glass microfibre of at least 250GSM.

Optical: These are even shorter pile than the Automotive Glass and Mirror microfibres. We have all seen these often very small cloths in with our sun glasses or with our mobile phones or laptops and they are very soft and smooth but are not very absorbent. They work great for polishing glass and are especially safe for gauge or touch screen surfaces.

What is GSM?

GSM stands for grams per square metre (g/m2). Material with a higher GSM weighs more than material with a lower GSM. It is typically thicker, and if there is a pile, it is more plush. Heavier cloths/towels will absorb more liquid than lighter towels. "GSM" is just a measure of density, not necessarily softness.

Most general use microfibres are between 200-350 GSM. Since the lower weights have a lower pile, they are less likely to streak or lint on glass, and are a bit more aggressive. Heavier weights are more durable, and have a more gentle cleaning action. 300GSM is the most popular weight for enthusiasts but increasingly this is nudging the 500/600 GSM mark!

Towels 360GSM and over are typically used for surfaces that need to be treated with extra care. The higher pile pulls debris away from the surface where it is less likely to scratch during the wiping process. As you start to edge towards 600+, then you're in the realms of coral fleece microfibres and extremely plush and hugely absorbent. Towels can get up to 1000 GSM+ but in our experience, these start to become heavy, so there is a fine line to consider when gauging performance over practicality!

Dual Pile Microfibre Cloths / Towels

Whilst this sub-heading may seem confusing and obvious, it’s to highlight the properties of the differing fibres on the cloth/towel! A dual-pile microfibre cloth is ideal for cleaning any shiny surface and with its 2 different microfibre threads on opposing sides, it’s specifically designed with a rough side for cleaning and a smooth side for polishing. This is noticeable in our Professional Microfibre Cloths and Towels and what makes them stand out from value cloths.

The rough side (used for cleaning rather than buffing) is made up of microfibre threads which are rough to the touch and can stick to your skin. Imagine a bunch of little loops of thread sticking out of the fabric. Now cut the tops off the loops, and you get a bunch of hooks (similar to Velcro). And like Velcro, these ‘hooks’ stay intact and work very well at removing stubborn dirt. Because your skin is covered in imperfections and ridges, these little ‘hooks’ stick to your skin and it feels prickly. It’s these micro-filaments that makes them so good at their job!

Cheap vs Quality Microfibres

"You get what you pay for" We've heard these words uttered many times and where your pride and joy is concerned, it's not worth skimping! Price doesn't necessarily dictate quality or indeed give you the full story on what you may expect! Knowing what's in your microfibre, how it's made and considering the guidelines documented here will dictate whether the microfibre is any good! The following are a few points to note when you're purchasing a microfibre you intend to use on your automotive surfaces:

- The cheapest of microfibres, those usually found in supermarkets and value stores are nearly always 100% Polyester. With no Polyamide content, these are way less absorbent than those with Polyamide. The microfibre thread is not split because the equipment necessary to produce this is very expensive (quality microfibres absorb 8-10 times their own weight because the fibres are split thus creating a larger surface area)

- Microfibre threads on value cloths are usually larger and usually up to 0.50 Denier in weight (quality microfibre threads are usually alot lighter 0.10 - 0.20 Denier)

- If you cannot read the description of the microfibre, GSM, Denier, Fibre content etc, then it's likely to be of low quality; if you produce a quality product, then you'll likely shout about it!

Microfibres can damage your paint!

Buy cheap microfibres and the construction will not be as good and the ‘ingredients’ as such will be inferior. Performance will be reduced as will durability. With cheaper materials used, there is a high chance that the microfibres can marr or scratch your paint – why? Well cheaper microfibres are cut using a ‘hot wire system’ and if not properly adjusted or maintained the hot wire will melt the fabric. When polyester and nylon melt, they turn into a hard plastic. Whilst this would be hard to identify in reality, we are talking very fine melted threads! Secondly, cheap microfibres lint. Microfibre lint is caused by cloths/towels with a high pile and/or a broad weave. This high pile and even loose weave allows the fibres to easily break off, creating lint.

Tip for drying your car with Microfibres

A slightly damp microfibre will dry your car far better and more effectively than a completely dry one! Why? because it absorbs water better than one that is fully dry! Scientifically speaking, the skin of a water molecule is polarised (attracted to specific molecules), thereby acting like a magnet for other liquid or water molecules based on a process known as 'capillarity'. Combine that with the hydrophilic qualities of microfibre towels, and you can see why the water on your vehicle is actually racing toward the water in the towel, anxious to bond!

Cleaning and Maintaining

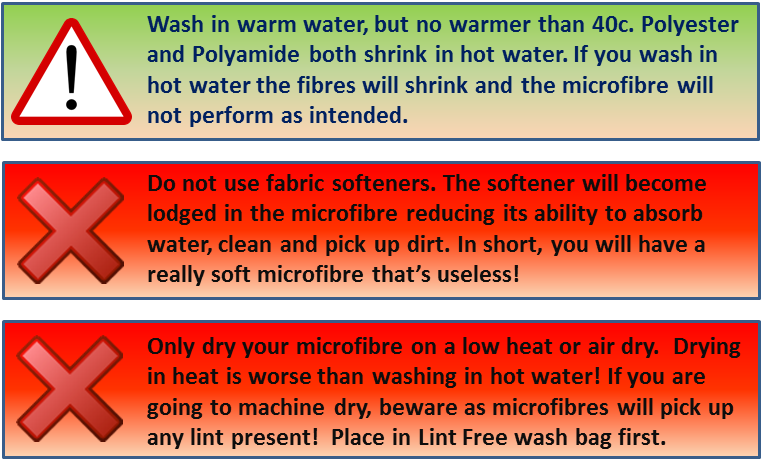

I have seen many school boy errors when it comes to cleaning microfibres. You can use detergents but only use liquid – powders often do not dissolve enough and the granules will lodge themselves into the weave. You can use washing machines, but only on a low heat setting and without fabric softeners. You can use a tumble dryer, but there in itself requires a few precautions - the fibres which are made up of varying proportions of Polyester and Polyamide will melt at higher temperatures and then once cooled will harden and potentially scratch your paintwork or the surface you are working on, therefore a very low setting is required if you want to use a tumble dryer! The best method is the old fashioned washing line! Here’s some notes of advice:

And finally….

Microfibre is an amazing product and can be used for so many tasks and configured in so many ways and this will only continue to expand in todays market. Hopefully this article will provide a bit more information on what you thought was just a soft cloth and help you evaluate what microfibres you have at your disposal and their best use. All of those cheap supermarket / value shop microfibres you may have still have a use, but just on non-delicate surfaces!